The Role of Metal Fabrication in the Agriculture Industry

The agriculture industry is one of the most important sectors for people all over the world. From cultivating crops to raising livestock, this industry is essential for global food production and sustainability. But behind the scenes, what keeps farms functioning efficiently is more than just soil, seeds, or skilled labor. It’s the equipment used every day, and at the core of this vital machinery lies metal fabrication.

Metal fabrication plays a critical role in creating durable, reliable, and specialized tools that drive agricultural operations. From tractors to irrigation systems, metal fabrication ensures the farm equipment needed to feed the world remains robust and efficient. To help you understand the role of metal fabrication in the agriculture industry , we’ll explore how it’s used, how it’s evolved, and what farmers and manufacturers can expect in the future.

The Evolution of Metal Fabrication in Agriculture

Agriculture has come a long way from its days of manual labor and wooden plows. The Industrial Revolution marked the beginning of significant advancements, as steam-powered machinery and basic metal tools began to reshape the face of farming efficiency. Early 20th-century developments, like tractors and motorized equipment, relied on metal fabrication to replace unreliable wooden components.

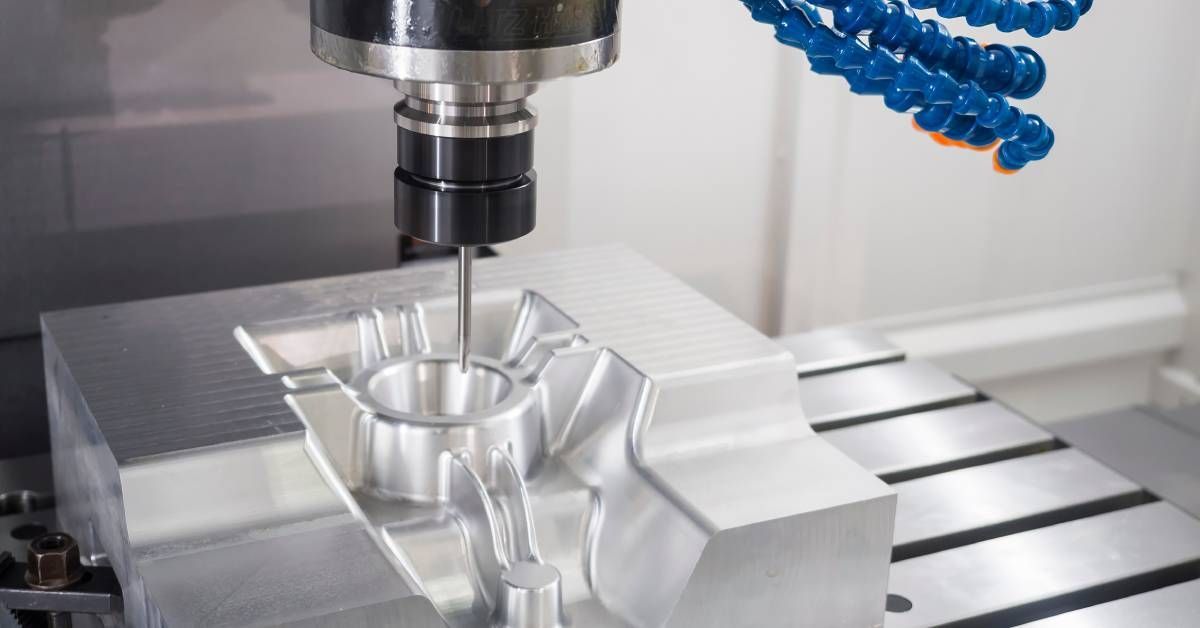

With time, new fabrication techniques, including welding, laser cutting, and CNC (computer numerical control) machining, have further advanced farming operations. Today, these techniques produce specialized components with precision, enabling farmers to improve productivity, conserve resources, and adapt to modern agricultural demands.

Key Components of Metal Fabrication for Agricultural Machinery

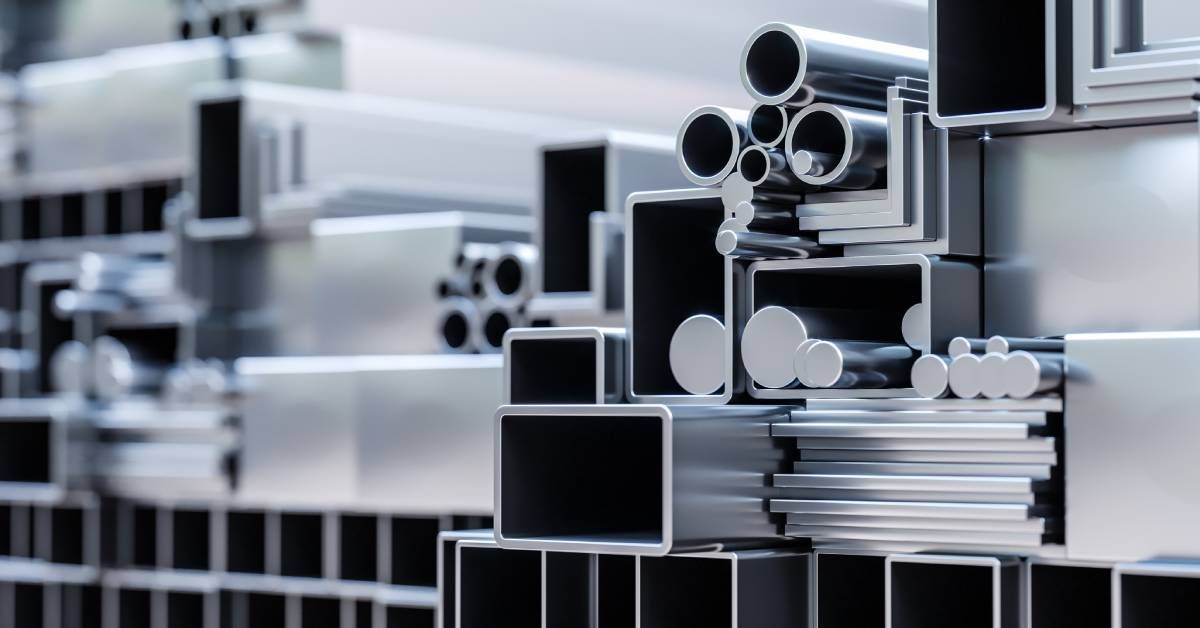

Metal fabrication creates customized solutions for the agriculture industry, focusing on parts that must endure tough conditions and demanding environments. Below are a few key components produced through fabrication:

Frames and Structures

Metal fabrication is responsible for producing strong, durable frames for tractors, harvesters, and other agricultural machinery. These structures must support heavy loads while operating over rough terrain, making quality fabrication essential.

Blades and Tillage Tools

Plows, tillers, and cultivators use specifically fabricated metal blades to cut through soil. The choice of metal and precision crafting ensures these tools remain sharp and long-lasting.

Irrigation Systems

Irrigation pipelines, sprinklers, and pumps require fabricated metal parts that resist corrosion and pressure fluctuations. Stainless steel and aluminum are common material choices due to their high durability.

Machinery Gears and Shafts

Fabricated metal components like gears and shafts power tractors and automated harvesting systems. Accurate machining of these parts ensures smooth operation and reduces machine downtime.

Storage and Transportation Equipment

Farm silos, bins, and trailers that store and transport agricultural goods also depend on metal fabrication to achieve both durability and weather resistance.

The Benefits of Metal Fabrication in Agriculture

High-quality metal fabrication is non-negotiable for the agriculture sector. These tools and machinery are investments for farmers, and the financial and operational consequences of equipment failure can be devastating. Some of the reasons to invest in quality machinery include:

- Durability and longevity: High-quality metal fabrication ensures that agricultural equipment can withstand harsh environmental conditions and heavy use, reducing the need for frequent replacements and repairs.

- Cost-effectiveness: Durable, well-fabricated components lower long-term operational costs by minimizing downtime and maintenance expenses.

- Precision and efficiency: Precisely fabricated metal parts contribute to smoother machinery operation, improving the efficiency and productivity of agricultural processes.

- Weather resistance: Properly fabricated metals are treated for weather resistance and protect against rust and corrosion, ensuring consistent performance throughout varying climatic conditions.

- Safety enhancements: High-quality metal components reduce the risk of equipment failure, promoting safer working conditions for operators and workers.

- Adaptability and customization: Advanced fabrication techniques allow for custom designs suited to specific agricultural needs, optimizing workflows and functionality.

As technology continues to advance, the agriculture industry will continue to benefit from innovative metal fabrication techniques and materials.

Future Trends in Metal Fabrication for Agriculture

With advancements in technology, the future of metal fabrication for agriculture looks brighter than ever. Several key trends are shaping the future.

Automation and Robotics in Fabrication

Automated robots and advanced CNC machines are expected to make the manufacturing process faster, cheaper, and more precise. This will allow for highly efficient production runs, even in custom projects.

Sustainable Materials

Sustainability is becoming a priority in agriculture. Fabricators are exploring the use of recyclable and eco-friendly metals to reduce waste and carbon footprints.

Integration with IoT and Smart Equipment

Metal components are being designed to house IoT sensors, which allow machinery to transmit real-time data about soil health, crop growth, and more. This innovation is bridging the gap between traditional agriculture and precision farming.

Additive Manufacturing (3D Printing)

3D printing with metals is emerging as a potential game-changer for creating lightweight, complex designs that would be difficult for traditional methods to replicate.

Tips for Quality Fabrication

While the future of metal fabrication may be exciting, it’s important to have robust policies in place to ensure your processes are well-coordinated. Heeding the following tips is a great way to streamline processes.

Select the Right Materials

The choice of metal or alloy plays a crucial role in ensuring the final product meets design requirements and performs effectively under specific conditions. Always consider factors like strength, durability, and resistance to corrosion when selecting materials.

Invest in Precision Equipment

High-quality fabrication relies on advanced machinery and tools that ensure accuracy and consistency. Regular maintenance of equipment is vital to prevent errors and maintain output quality.

Employ Skilled Technicians

Experienced and trained professionals are essential for achieving precise and reliable fabrication results. Skilled technicians can identify potential issues early and ensure the proper execution of complex designs.

Follow Strict Quality Control Procedures

Implementing a robust quality control system at every stage of the fabrication process helps catch imperfections and ensures the product aligns with specifications.

Optimize Design for Manufacturing

Work closely with design teams to develop models that are feasible for manufacturing, reducing complexities and minimizing material waste during production.

By adhering to these best practices, fabricators can achieve superior results while optimizing efficiency and reducing costs.

Fabricating In-House vs. Hiring a Professional Service

One of the biggest decisions agriculture businesses face is whether to fabricate components in-house or hire a professional fabrication service. Here’s a quick comparison to help you decide:

Fabricating In-House:

- More control over production timelines

- Higher upfront costs for machinery and skilled labor

- Requires ongoing maintenance of equipment

Hiring a Professional Service:

- Access to advanced tools and expertise

- Reduced capital investment in machinery

- Ensures high-quality, reliable results

- Frees up time and resources for core farming activities

Professional fabrication services often provide a more cost-effective solution for small- to medium-sized farms.

Moving Forward With Metal Fabrication in Agriculture

Metal fabrication is essential for modernizing agricultural operations, supporting productivity, and ensuring the longevity of farming equipment. By exploring the role of metal fabrication in the agriculture industry, farmers can enhance efficiency, reduce downtime, and stay competitive in today’s demanding market.

Looking to optimize your agricultural machinery with expertly fabricated components? At H&H Machine, our steel fabrication services are designed to streamline your operations, ensuring your manufactured products are up to the most critical tasks. Reach out to trusted metal fabrication professionals who can help you achieve the durability and precision your farm deserves!